Production Areas

Production Areas

Automotive & General Industry

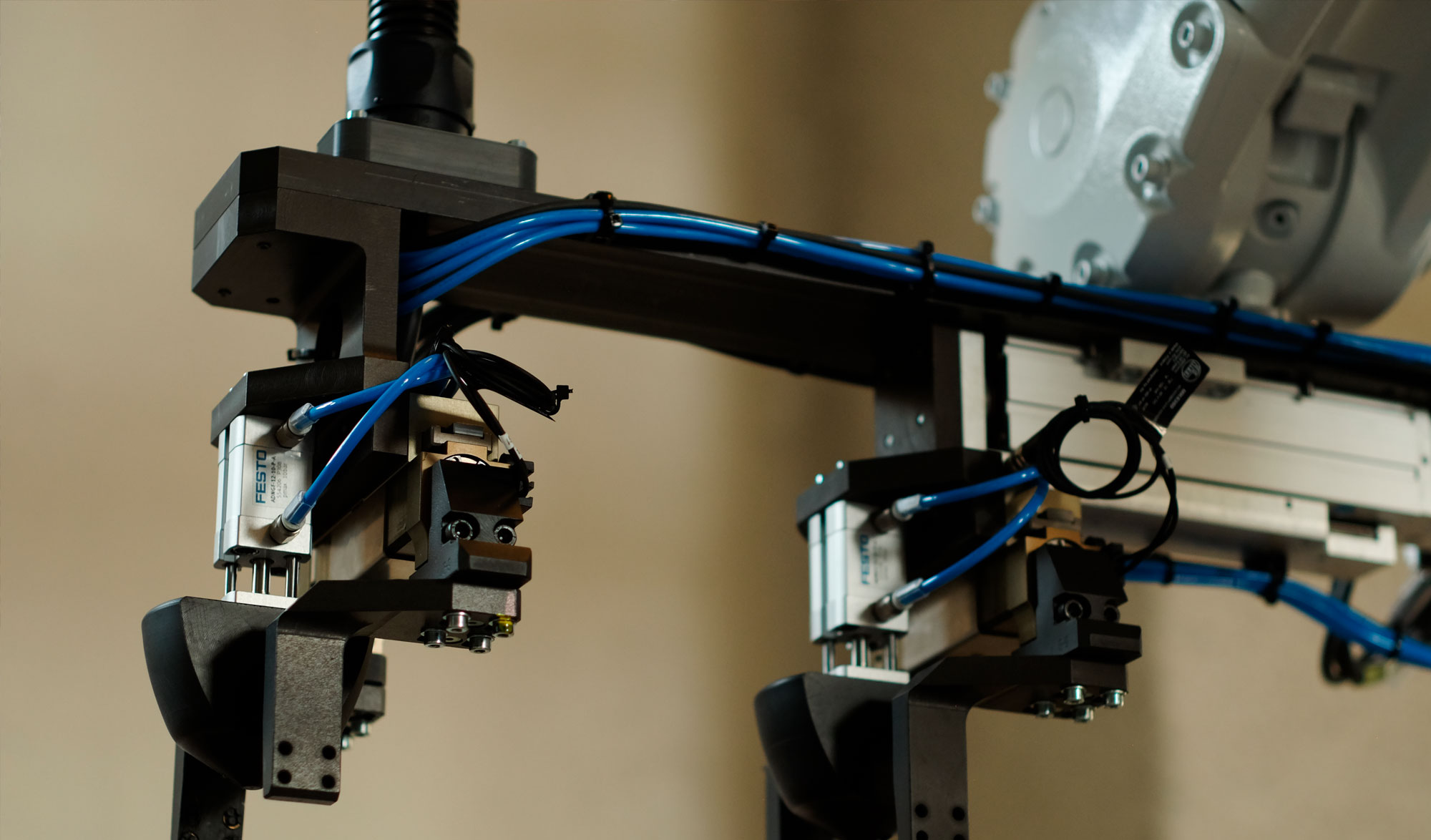

The robotic cells for tools machine interlocking are the first to be born, with the aim of replacing the operator in those extremely heavy or repetitive work phases. To date, the demand to meet this need remains high, which finds a solution in the construction of individual plants or real production lines that provide for the enslavement of all the machines in process.

Autonomy and efficiency are the keywords of this type of robotic cells.

Autonomy and efficiency are the keywords of this type of robotic cells.

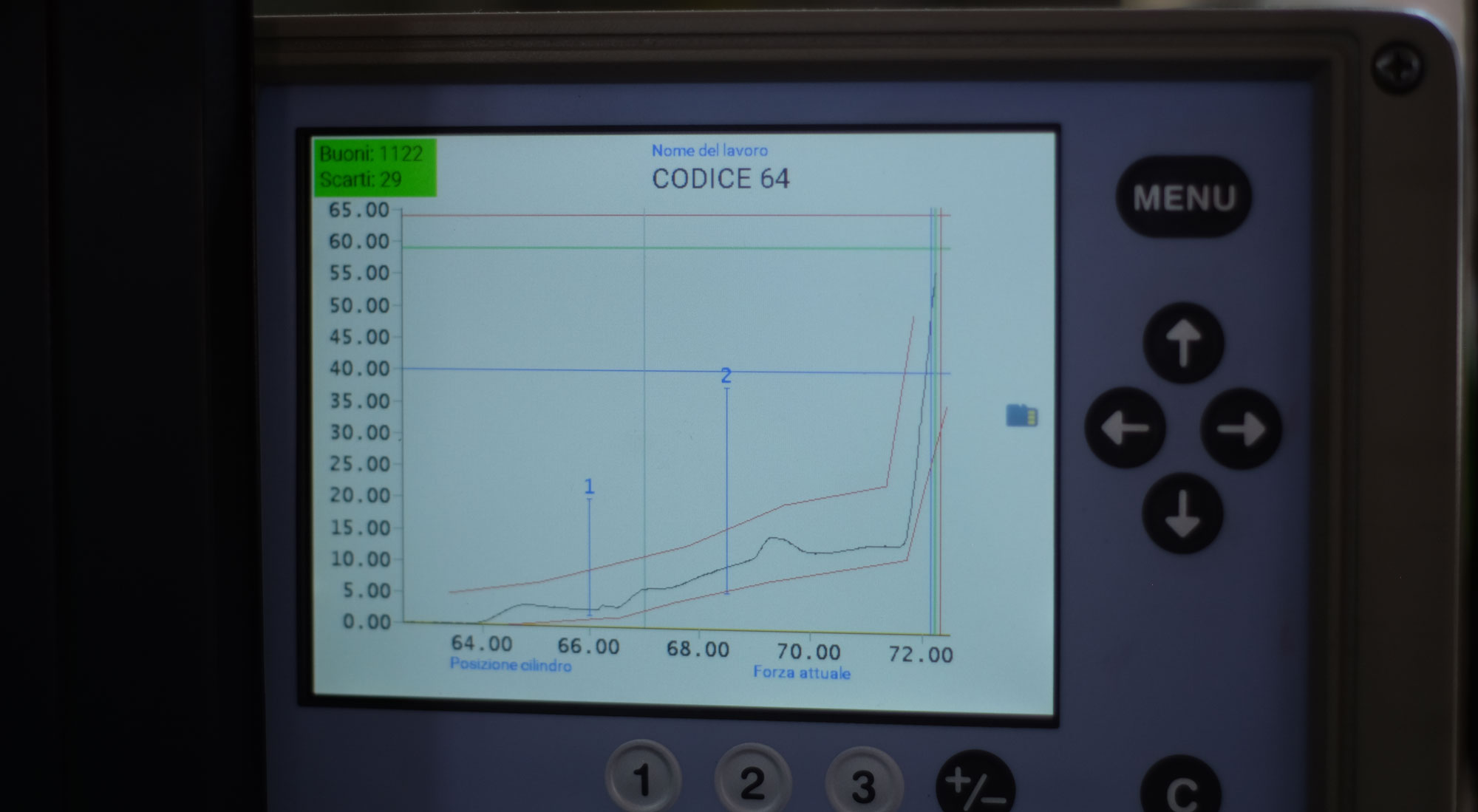

Component Assembly and Testing

The automation of the assembly and testing phases can include the use of both collaborative and traditional robots, depending on the working area to be covered and the required cycle time.

The cells are usually completed by automatic feeding systems, able to guarantee considerable autonomy without the supervision of the operator, and by unloading systems with directing of the finished parts outside the cell. In this specific Area we focus on automatic robot-machine hybrid solutions in order to build efficient and, above all, flexible cells.

The cells are usually completed by automatic feeding systems, able to guarantee considerable autonomy without the supervision of the operator, and by unloading systems with directing of the finished parts outside the cell. In this specific Area we focus on automatic robot-machine hybrid solutions in order to build efficient and, above all, flexible cells.

Automatic Palletization

The possibilities to automate this type of operations are many, both starting from the pieces packaging and canning phases, through also the use of high-resolution vision systems, also focusing only on end-of-line palletizing operations, thanks to the opportunity to be able to program countless palletizing schemes.

Also in this case, they are used collaborative or anthropomorphic robots depending on the weight to be handled and the working area to be covered.

Also in this case, they are used collaborative or anthropomorphic robots depending on the weight to be handled and the working area to be covered.

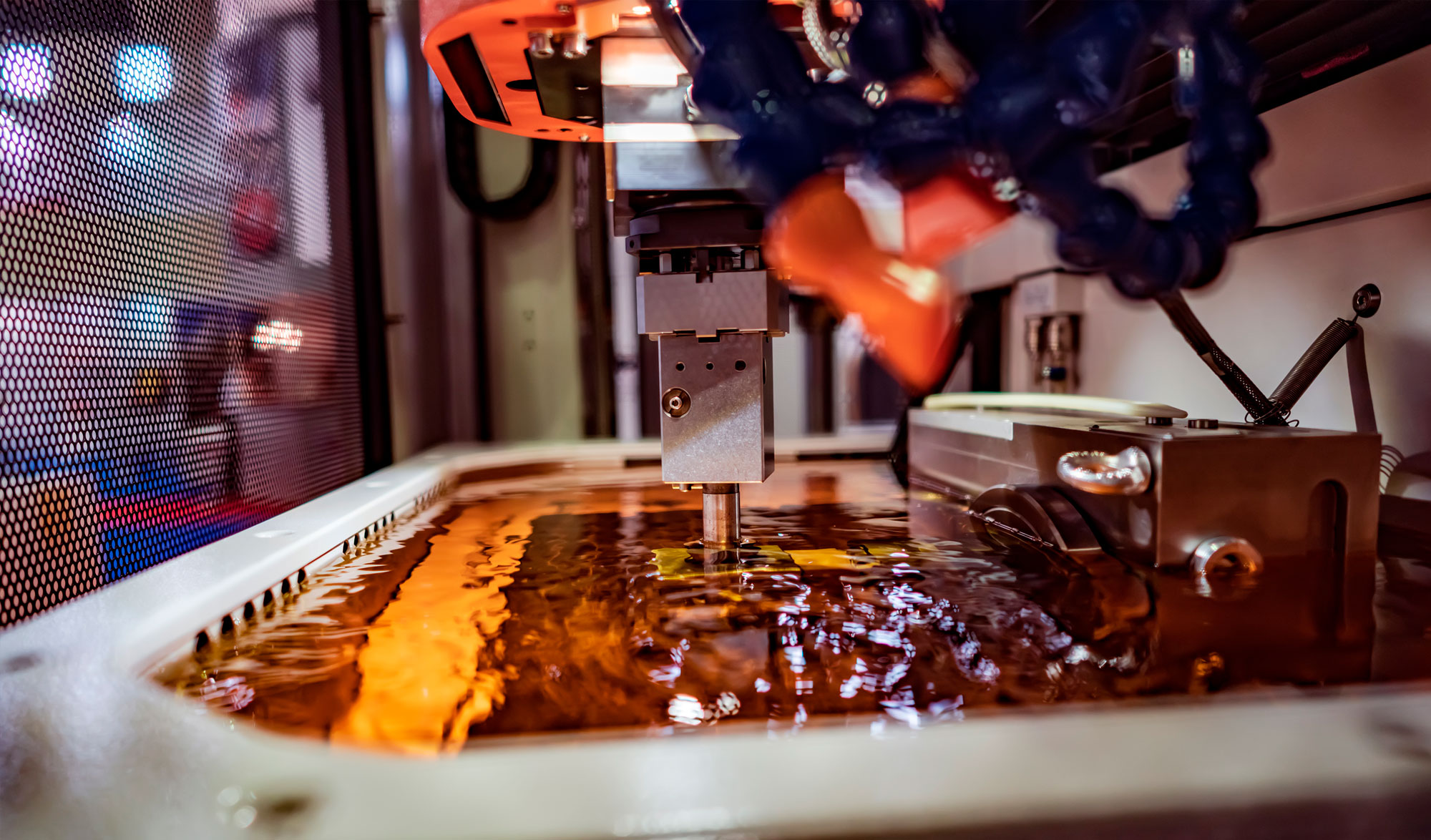

Foundry

Foundries increasingly need high-performance systems, often multirobots, which, in addition to the part handling (just casted) integrate figure controls, blanking and cooling, but also traceability markings.

We are also active in the automation of the gravity casting process, handling and preparation of forming or de-blocking cores.

We are also active in the automation of the gravity casting process, handling and preparation of forming or de-blocking cores.

Pharmaceutical & Healthcare

The use of robots for “white rooms” or “clean rooms”, designed to operate in sterile production environments, makes the automation possible even in the healthcare, pharmaceutical and electronics Areas, where performance must necessarily travel hand in hand with a high level of protection and cleanliness.

Aerospace

The aerospace Area needs specific machines, often built specifically for individual products. The robots are inserted in the tools loading and unloading, in the handling and control of the product or in the handling of products that would not be handled manually, both for ergonomics and surface contamination problems.

Food

Regarding the food Industry, the most requested application is that linked to the product packaging and end-of-line palletizing phases.

The product packaging and boxing operation is often also assisted by the use of high-resolution vision systems, while the possibility to programm countless off-line palletizing schemes makes the commissioning phase of end-of-line palletization quick and fluid.

Also in this case, collaborative or anthropomorphic Robots are used depending on the weight to be handled and the working area to be covered.

The product packaging and boxing operation is often also assisted by the use of high-resolution vision systems, while the possibility to programm countless off-line palletizing schemes makes the commissioning phase of end-of-line palletization quick and fluid.

Also in this case, collaborative or anthropomorphic Robots are used depending on the weight to be handled and the working area to be covered.