Virtual Commissioning

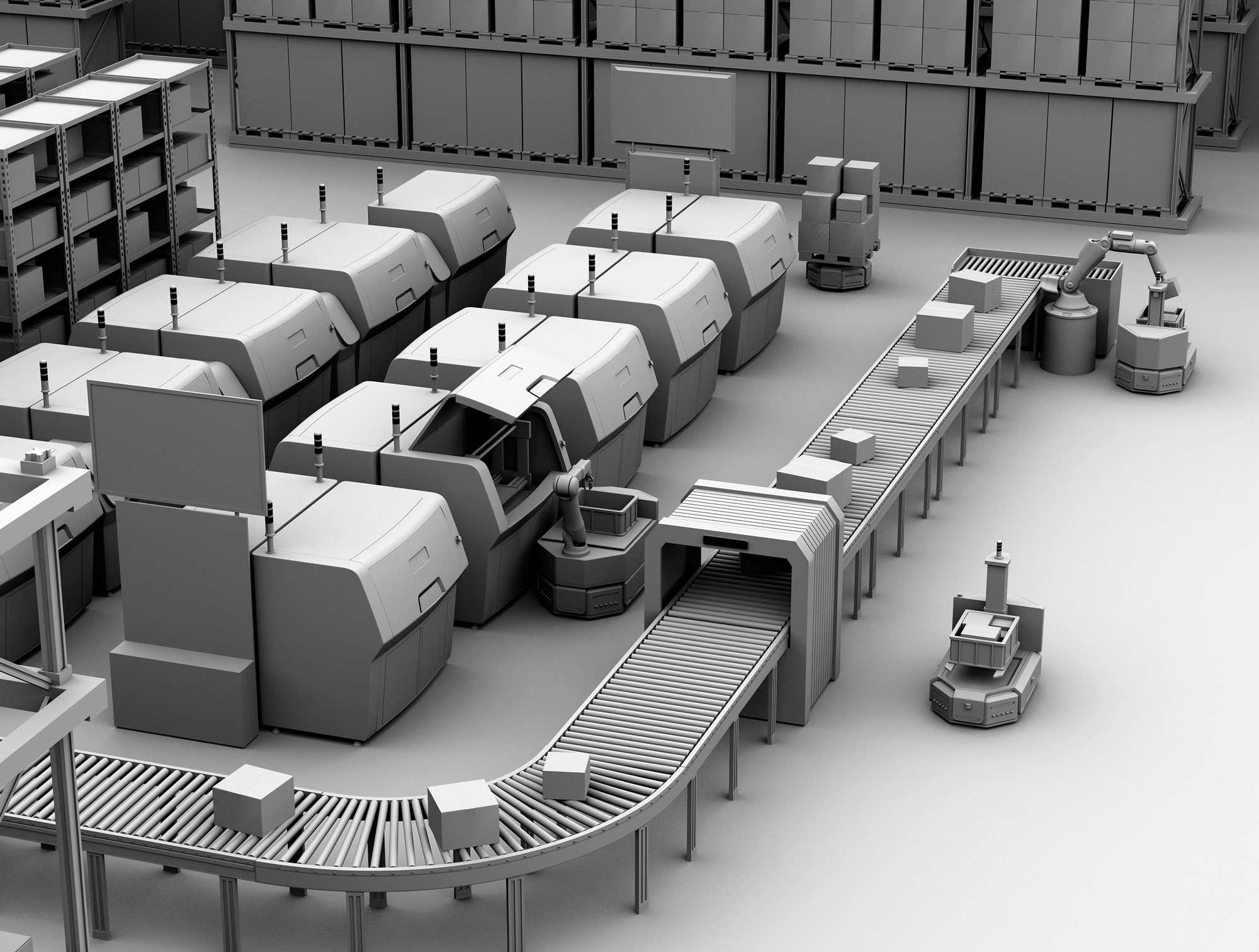

Virtual commissioning

In Robot at Work, Innovation is the watchword par excellence and it is therefore easy to understand that R&D activities play a fundamental role for us.

It is thanks to this motivation towards the new, that we have approached Digital engineering and Virtual Commissioning, fundamental instruments for those who move in our sector.

Giving the customer the opportunity to view both the robotic system and its integration into the existing production line, even before i twill be achieved, is the first of a series of significant advantages:

• Digital definition of the new application in detail, with well-defined performance and solutions right from the start;

• Interactive sharing with the customer of the cycle time, the strengths or any critical issues of the project, before freezing the start of the hardware realization of the order;

• Thanks to the digital interaction between the mechanical, electrical and software parts (robots, plc & scada), it is possible to develop the project down to the smallest detail, reducing what is usually the most expensive phase of a job, that is the actual realization;

• Reduction of installation times at the customer and possible unforeseen events.

• Interactive sharing with the customer of the cycle time, the strengths or any critical issues of the project, before freezing the start of the hardware realization of the order;

• Thanks to the digital interaction between the mechanical, electrical and software parts (robots, plc & scada), it is possible to develop the project down to the smallest detail, reducing what is usually the most expensive phase of a job, that is the actual realization;

• Reduction of installation times at the customer and possible unforeseen events.

In a single environment

At the software level, we develop our projects using the Dassault Systèmes 3DExperience® platform, which, thanks to the Delmia software, is able to connect the real world with the virtual one.

It is of fundamental importance to be able to have a real-time view of the business and ecosystem of the company, being able to connect people, ideas and data in a single collaborative environment.